Today, with the dual upgrading of electric vehicle range anxiety and energy storage safety requirements, the accuracy and stability of battery management systems (BMS) have become the core competitive points in the industry.

Faced with the urgent demand for "safer, more accurate, and more intelligent" high-voltage battery packs in the market, ADI has launched a heavyweight attack - the latest ADBMS2970 battery pack monitor, with its high-precision, low error, and EIS detection system, provides "chip level" safety protection and health diagnosis for high-voltage battery packs.

This article will analyze the technical characteristics of ADBMS2970 and reveal how it can become a "battery doctor" in the field of new energy through real-time monitoring of current, voltage, and battery capacity, providing protection for the safe operation and efficient management of high-voltage battery systems.

ADBMS2970 is a battery pack monitor chip mainly used for electric and hybrid vehicles, as well as other current or voltage sensing detection. It is an important component of automotive battery packs.

This chip supports EIS current channel and EIS battery pack voltage measurement. EIS stands for electrochemical impedance spectroscopy. Its working principle is to accurately apply millivolt level sinusoidal alternating current to the battery through a current channel, and then analyze the electrochemical processes inside the battery by monitoring the impedance's frequency variation. This process is like doing an "electrocardiogram" and "CT scan" for a battery pack, which can more accurately diagnose its health status. It is worth noting that the ADBMS2970 can synchronously measure the impedance of multiple batteries and accurately calculate the degree of battery pack loss through Coulomb counting.

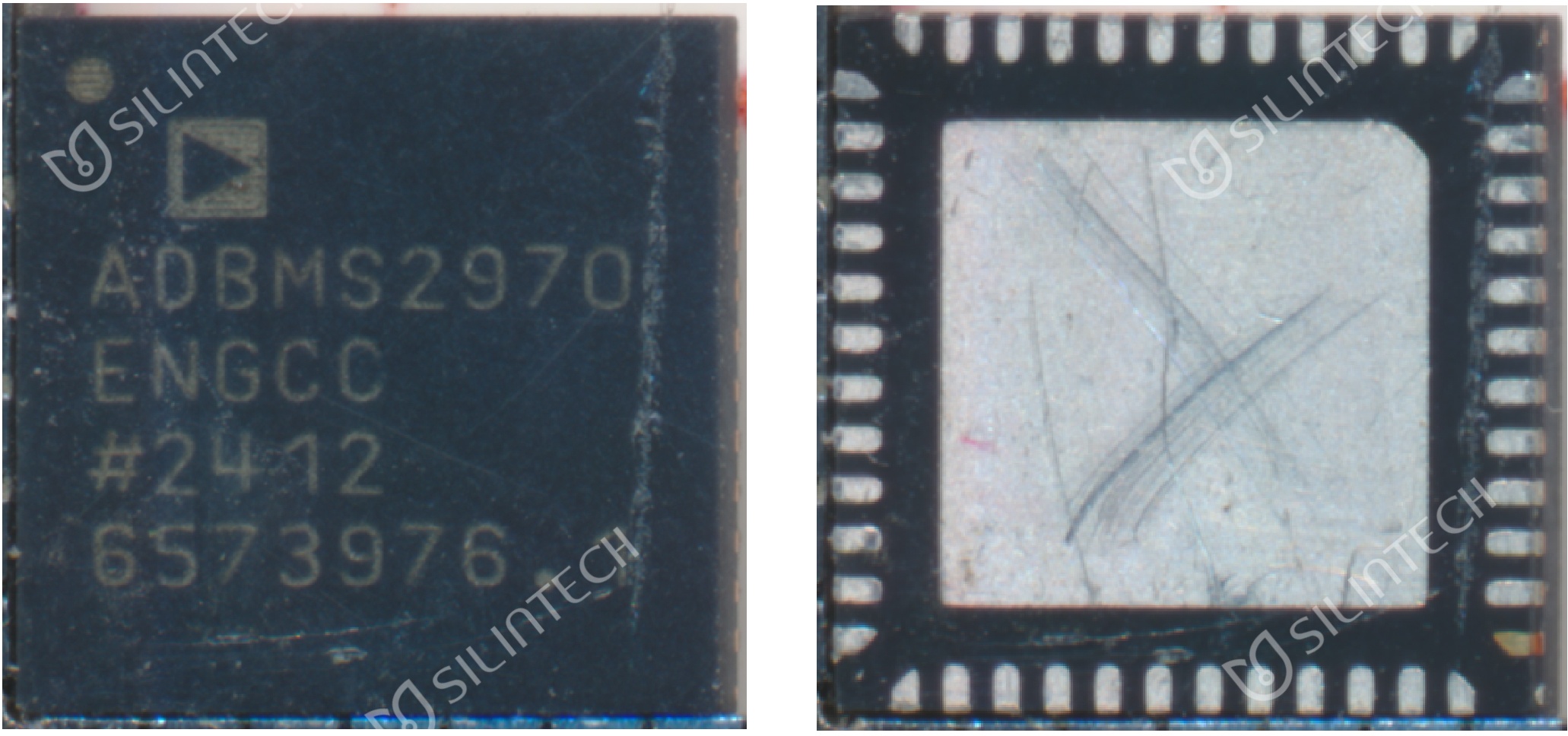

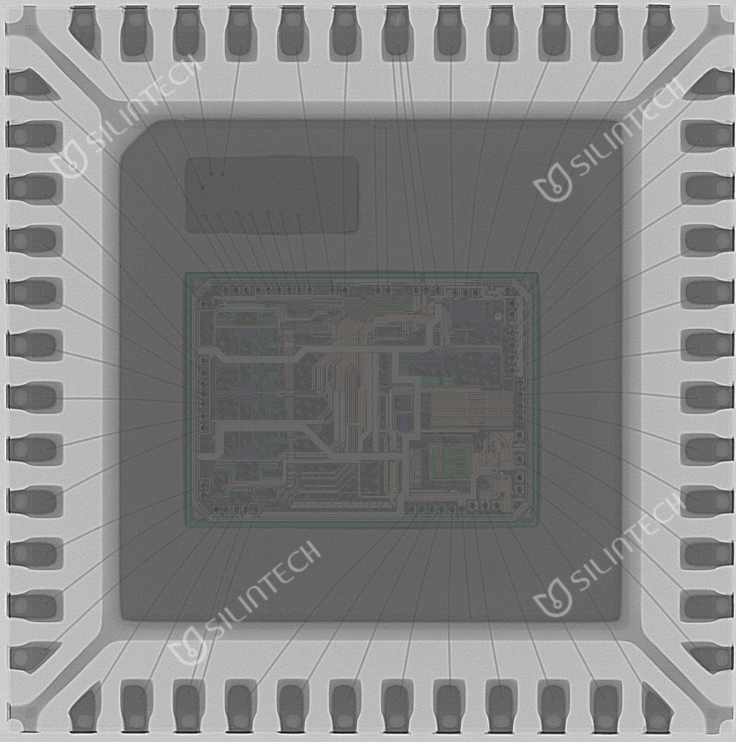

Firstly, let's take a look at its packaging and X-ray. The ADBMS2970 adopts the QFN-48 packaging, which has the characteristics of small area and high heat dissipation. From the X-ray, it can be clearly seen that ADI continues to use the previous dual die structure, where one large die is responsible for the main function of the chip, and the other small die serves as a reference voltage.

ADBMS2970 Packaging Diagram

ADBMS2970 X-ray image

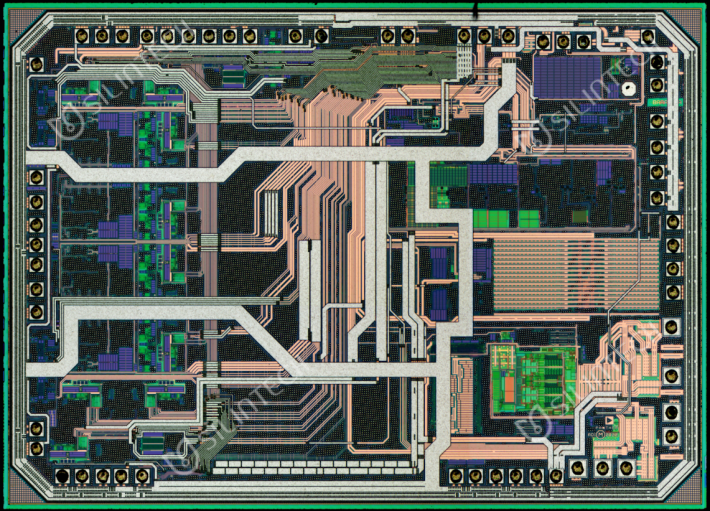

Top level Overview of ADBMS2970

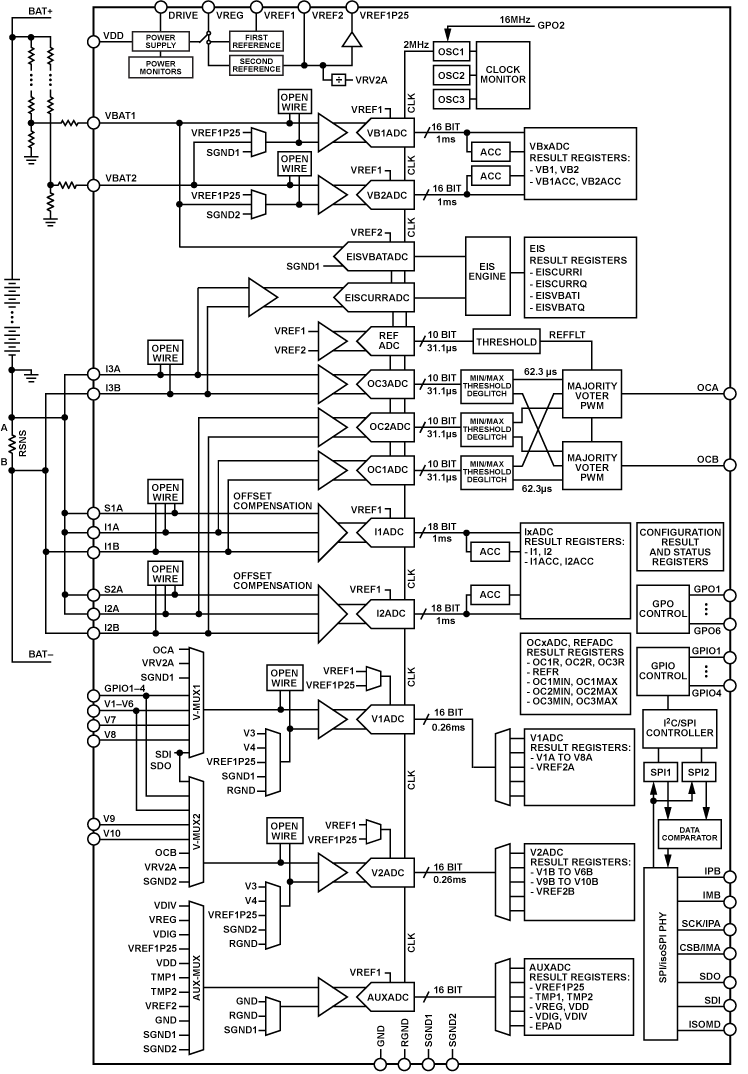

Based on the structural diagram and chip characteristics, it can be seen that the ADBMS2970 adopts multiple high-precision ADC designs to achieve EIS current detection by measuring the voltage drop across the same shunt resistor, while also measuring the current and voltage flowing into and out of the battery pack.

ADBMS2970 Structural Block Diagram (Source: ADI Official Website)

This chip provides 12 dedicated buffered high impedance inputs, which can be used to measure battery pack voltage or extend measurement of temperature, HV Link voltage, and even fuse status. We learned from the chip manual that with some configurations, it is possible to further expand the buffer high impedance input to 20 and increase the number of measurement ports.

The ADBMS2970 also has 6 digital outputs that support open drain or push-pull modes, which can be used to control external high-voltage transistors to control the on/off of resistive dividers.

As a member of the ADI battery management system, the ADBMS2970 can also communicate with other BMS controllers through serial interfaces or connect to other battery management components through additional isoSPI ports, achieving system expansion and coordinated operation.

Silintech is currently conducting in-depth and systematic analysis work on this chip. If you want to learn more about the technical details of this chip, please feel free to contact us at any time. We will be dedicated to providing you with professional answers and technical support.

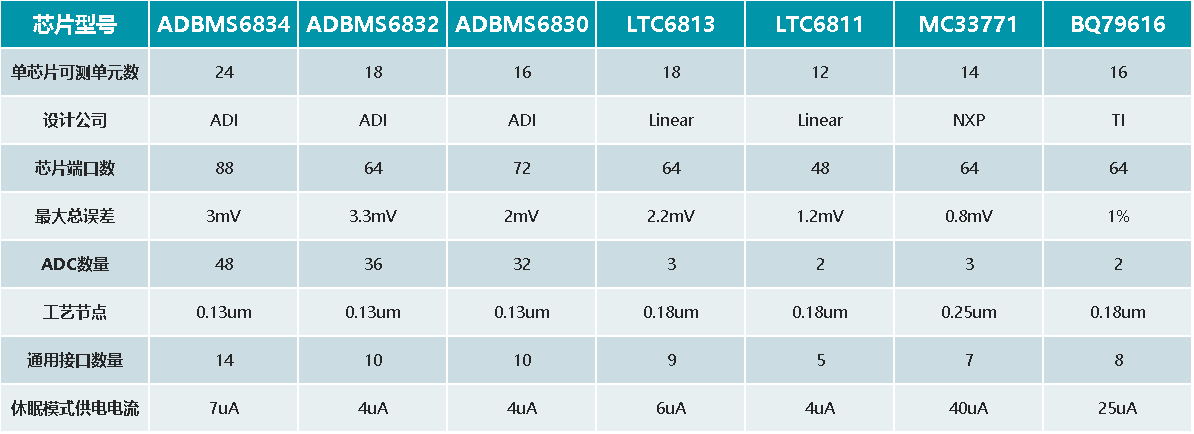

Comparison of BMS chip performance

Performance comparison of BMS chips with completed circuit analysis by Silintech:

The data in the table is based on the chip manual provided